The continental shelf of Russia

The original total resources of hydrocarbons in the continental shelf of Russia reach almost 100 billion tons of reference fuel, 80% of which is gas. Most hydrocarbons (more than 80%) are concentrated on the floor of the Barents Sea, Pechora Sea, Kara Sea and the Sea of Okhotsk. This being said, gas and condensate prevail on the floor of the Barents Sea and Kara Sea, oil is mostly found in the Pechora Sea, and oil & gas resources are located in the Sea of Okhotsk.

Today, the main projects of Gazprom in the Russian continental shelf area are:

● Sakhalin-2 and Sakhalin-3 in the Sea of Okhotsk;

● Shtockman gas condensate field in the Barents Sea;

● Prirazlomnoe anf Dolginskoe fields in the Pechora Sea;

● Severo-Kamennomysskoe and Kamennomysskoe-sea deposits in the water areas of the Ob Bay and the Taz Bay.

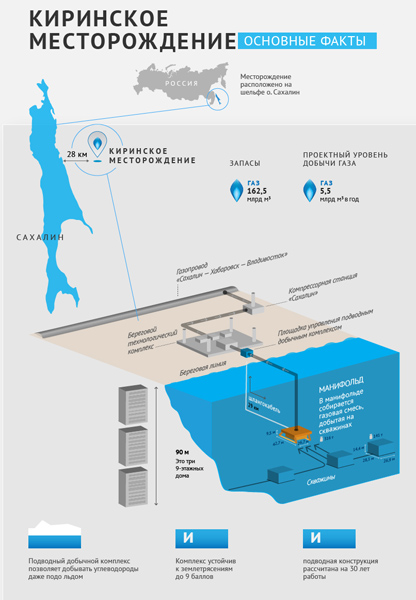

The Kirinsk field is a part of Sakhalin-3 project. For Gazprom, it is a top-priority target of development of the Sakhalin shelf. It will become one of gas supply sources for customers in the Far Eastern regions of Russia. This facility was completed in record-breaking time (it took 3 years only) in severe climatic conditions, using the most complex shipping logistics. The field commissioning will improve the gasification level and provide a required experience for development of other deposits in the continental shelf.

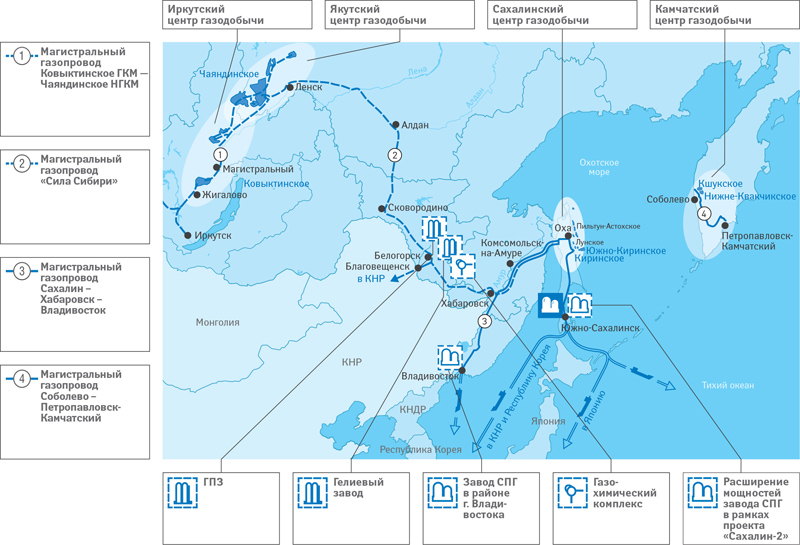

Scenario of resources development of Eastern Siberia and Russia's Far East

Eastern gas program

Development of the continental shelf in the East of Russia is performed as part of the Eastern gas program approved in 2007 by order of the Ministry of Industry and Energy of the Russian Federation. The top-priority tasks of the Eastern gas program include establishment of new gas production centers in the Irkutsk region, Krasnoyarsk Territory, the Sakha Republic (Yakutia), the Sakhalinsk region (Sakhalin island shelf), and Kamchatka Territory, as well as gasification of the Eastern regions of Russia. Also, the program implementation will make it possible to export gas to the Asia Pacific market which will be comparable to the European market in terms of sales volume. Gazprom was appointed by the Government of the Russian Federation as the Eastern gas program coordinator.

Sakhalin island shelf

Sakhalin island shelf

By developing the Sakhalin center of gas production, Gazprom is performing intensive works on the Sakhalin shelf in the Sea of Okhotsk (Sakhalin-2 and Sakhalin-3 projects). In Sakhalin-3 project, Gazprom owns four production licenses for exploration of Kirinsk, Ayashsk, East-Odoptinsk zones and the Kirinsk field. Total estimated gas resources are about 1.1 trillion m3. The Sakhalin-3 gas will ensure gas supplies to the Far Eastern regions and implementation of Vladivostok-SPG project.

The Kirinsk field

Gazprom Dobycha Shelf LLC is the customer and the operator of the investment project “Construction of the Kirinsk gas condensate field” (part of Sakhalin-3 project).

For the first time ever, production from the field in the Russian shelf will be carried out with the use of subsea production facilities. i.e. with no above-water structures involved.

The deposit was discovered in 1992. It is located in the shelf of the Sakhalin island about 30 km away from the shore where water depth reaches 80-90 meters. C1 gas and gas condensate reserves of the deposit amount to 162.5 bln m3 and 19.1 mln tons respectively. The gas from the Kirinsk field will be transferred via the gas pipeline “Sakhalin – Khabarovsk – Vladivostok”. That will ensure gas supply to major industrial consumers in a few Far Eastern regions (Khabarovsk and Primorsk Territories, Jewish Autonomous Region). The state-of-the-art machinery and equipment was used during deposit construction works. Specialized vessels of Russian and western companies performed laying of subsea pipelines and control umbilicals, assembly of the subsea production facility equipment. For well construction at the Kirinsk field, a new Gazprom’s semi-submersible drilling rig “North Star” was used. The rig was fabricated on request of the company by Vyborg Ship-Building Yard. This is the latest-generation marine drilling rig; state-of-the-art technologies and equipment were used for its fabrication. The platform is designed for operation in the most severe climatic conditions, is able to sustain the wave height up to 32 meters and is able to perform exploration and production drilling of gas and oil wells up to 7500 m at a depth of 70-500 meters.

Production technology

For the first time ever, construction of the Kirinsk gas condensate field was carried out with the use of a subsea production facility (SPF). To deliver the required equipment to the Kirinsk GCF, complex activities were performed related to the equipment shipment from different regions of Russia and from abroad to the Sakhalin island. For example, a Christmas tree for Kirinsk field wells and a manifold (which is the main component of the subsea production facility) had to be delivered from Larvik and Langesund seaports, Norway.

Subsea production facility

Subsea production facility

The subsea production facility allows producing hydrocarbons under the most severe climatic conditions, even under the ice, with no platforms or other above-water structures required. Similar technologies were already used in other countries such as Norway (Snevit and Ormen Lange fields), but the Kirinsk field was the first time they were introduced in Russia. A subsea production facility is free from any atmospheric pollutant or noise emissions. The facility is located in a seismically active zone so the equipment for the Kirinsk field was designed and constructed with due account of that fact and is resistant to earthquakes up to magnitude 9.

The subsea production facility will consist of 7 wells wherefrom gas will be delivered to the manifold via a pipeline. The manifold itself, including its base, is really enormous. Its dimensions may be compared to a 3-story building, and its weight is more than 300 tons. The manifold consists of a set of pipelines with switching shutoff valves fixed on the same base, designed for high pressure, and connected to each other according to a special diagram. The gas mixture produced from the wells of the field is collected in the manifold and then transferred to the shore processing unit for treatment and further transportation via the system of gas mains.

For construction of the onshore processing facility (OPF), Russian technologies were mostly used. Russian companies have designed and fabricated complex processing equipment to ensure trouble-free operation of the subsea production facility. The gas / gas condensate treatment unit is also fit with domestically manufactured equipment. For the purpose of cost optimization during construction of deposits of the Kirinsk block, OPF production facilities will be used for development of South-Kirinsk and Mynginsk fields.

Environment

Gazprom Dobycha Shelf LLC pays special attention to environmental safety on all stages of development of offshore fields. Unique nature of the Far East is very vulnerable and sensitive to man-induced impact. That is why strict compliance with Russian and international environmental codes and standards, environmental friendliness, and prevention of negative impact on marine and terrestrial ecosystems are reference conditions of all projects of Gazprom Dobycha Shelf LLC.

For the purpose of obtaining continuous information on the environmental situation at the Kirinsk field, industrial environmental control and monitoring of the environment are conducted.

Thermal treatment facility

Thermal treatment facility

On site, there is a thermal treatment facility where domestic sewage and industrial wastes are being incinerated which results in zero pollution of the water area of Sakhalin. As of today, two Russian projects use this technology, but the most powerful facility is installed at the Kirinsk field.

Starting from 2012, Gazprom Dobycha Shelf LLC has been implementing biodiversity conservation programs on the territory of the Sakhalinsk region aiming to minimize the environmental impact at all stages of companies’ operating activities and to protect endangered and threatened species of animals and plants.

Outlook

In October 21013, first gas was released at the Kirinsk field. The system of gas supply from the subsea production facility to the onshore processing facility has passed the test successfully.

Solemn ceremony of the first gas release at the Kirinsk field

Solemn ceremony of the first gas release at the Kirinsk field

Currently, there is one producing well constructed at the Kirinsk field. Six more are scheduled for construction. Assuming full development, the planned production level will reach 5.5 bln m3 per year. At the next stage, field facilities are supposed to be constructed for the South-Kirinsk field, the largest deposit of the Kirinsk block. C1+C2 resources of the South-Kirinsk field amount to 563.9 bln m3 of gas and 71.7 mln tons of gas condensate. Eventually, it is planned to develop the Mynginsk field as well. Development of the abovementioned deposits will be performed by means of installation of subsea production facilities with the use of the infrastructure of the Kirinsk field.

Successful implementation of the shelf development project in the Sea of Okhotsk will affect many development aspects of the Sakhalinsk region and the Far East. First of all, the level of the regional gasification will improve significantly. The cities of Siberia and the Far East will transfer from using oil residue and coal to the more environmentally friendly fuel which will result in reduction of atmospheric emission of pollutants and improve the environmental situation in those regions. Economic activities are expected to become more intense which will be related to equipment repair, procurement, maintenance of transport facilities, and other production services. Direct investments are raised for Sakhalin which results in economic incentives, increase of income of the regions, infrastructure upgrades, and extra job opportunities.

Public and Mass Media Relations of Gazprom Dobycha Shelf LLC

Photos and pictures by the author

First photo: semisubmersible drilling rig “North Star”

(С) Медиапортал сообщества ТЭК www.EnergyLand.info

Оформить подписку на контент Looking for authoritative content?

Копирование без письменного разрешения редакции запрещено