At least the crisis has affected a group of oil-immersed transformers 6 and 10 kV. Decline there is 20-25%. According to the Director of Marketing and Sales Company LLC "BaltEnergoMash" (Moscow), Dmitry Zhuravlev, the stability of this segment has been provided by the fact that much of this equipment is used in major repairs, which is enough problematic to delay. In addition, General Director of JSC "Transformer" (Podolsk) Eugene Lyakhnitsky noted that on oil transformers had switched some customers which previously were oriented on more expensive dry-type transformers. After a brief fall, demand for oil transformers began to recover. Here is what the director for science and innovation program OAO ELEKTROZAVOD "(Moscow) Viktor Kovalev says about this situation:" The demand for transformers 6 and 10 kW in 2009 decreased approximately on 25%. But by the summer we felt the revival of the market, and year-end business of our company completed the planned production and sales of this type of product "...

During the year, were determined and transformers - "outsiders of market. Viktor Kovalev in particular refers to the significant decline in demand for Furnace transformers and special transformers for metallurgical industries. Curiously, in the same year, the crisis showed that a good solution for manufacturers will be to focus on the production of highly specialized transformers, for which demand was high enough.

Figure 1. According to the EAC "VladVneshServis"

At summer transformer’s market has almost stopped shrinking and sales went up. As noted Eugene Lyakhnitsky: "By the end of the year, we not only reached the previous volumes, but also completely eliminated the warehouse stock. Representatives of several marks a return to previous positions. And in some segments the growth in the autumn months was very noticeable. In particular, custom’s statistic shows a strong positive dynamics of transformers export ranging from 16 to 500 kVA. During September-November 2009 sales reached about $ 1.2 million. Increase of interest in September and October amounted to 122% and 15%. Experts of information-analytical company "VladVneshServis" say that such statistics allows us to consider this market segment as a fairly promising.

TABLE. 1 Dynamics of export and import of transformers in recent years.

Information is provided by EAI "VladVneshServis» http://vvs-info.ru/

Price dynamics

In 2009, was changing not only sales, but prices on transformers. During the first half of the year the price on some items was reduced on 20%. This is consistent with the market. Thus said the head of the transformer “ROSPOL-ELECTRIC +"(St. Petersburg), Maria Andreeva:" If in the middle of 2008 the selection of equipment was due to ratio price / performance , then in 2009, trying to minimize costs, customers were guided by value . Commercial Director of "BETRANS" (St. Petersburg), Sergei Gridnev noticed that the prices of producers are strongly influenced by increased price competition. Prices of factories-manufacturers changed several times, - says Sergey. - From the beginning, the prices decreased, and from the 1 November had increased.

The period of minimum prices for producers of transformers was difficult. At the beginning of the year, some manufacturers of transformers stated that, by lowering prices on component they may decline prices on finished goods. However, as remarked Head of Commercial Department LLC "KRUELTA" (producers KRA and transformer substations, St. Petersburg), Dmitry Avdeev, the signal of lowering prices on components the market did not. Moreover, in some cases, component manufacturers had increased prices in proportion to inflation. The cost of imported materials is adjusted depending on exchange rates. Similar figures were given by senior manager of marketing department of OAO "Sverdlovsk Plant of Current Transformers" Alexander Smirnov: "During the crisis, some materials such as copper, fall in price but at the same time went up electrical steel. In addition, we use imported materials, whose prices are tied to the euro or the dollar. The price of the imported compound, essential for the production of dry transformers with cast insulation, for the year grew by nearly 30%.

Oil Renaissance

Rising of prices on imported components became one of the reasons for the rising of popularity of oil-immersed transformers. They used to be cheaper than dry, but due to higher prices for components, the difference in prices for dry and oil transformers had reached nearly three times the size. According to chief designer of the department of power transformers OAO "Sverdlovsk Plant of Current Transformers" Andrew Gusakov, producing of oil transformers have more abilities for leeway in building the pricing policy. Models of oil transformers are manufactured in Russia for many years, and the domestic industry has learned to produce components for them in acceptable quality. Dry transformers are a novelty. In Russia we cannot produce such materials for molded insulation. Manufacturers have to purchase compound (resin) and a number of elements abroad. In this

period currency fluctuations inevitably leads to high prices on dry-type transformers, manufactured in Russia.

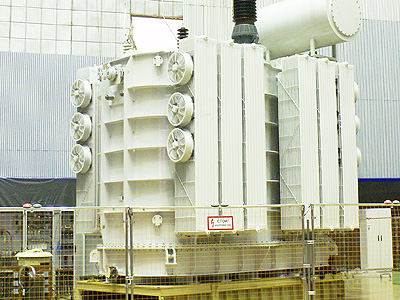

period currency fluctuations inevitably leads to high prices on dry-type transformers, manufactured in Russia.Figure 2 Despite the decline in popularity of dry-type transformers, OAO SPCT is putting on market a line of force CLW

Nevertheless, producers and customers of transformers are confident that over time interest to the dry transformers will restore. In Europe, for example, today 80-90% of installed transformers - dry with cast insulation. They are less flammable, more compact, require less care and can work where the use of oil-immersed transformers is impossible. Actually, in Russia before the crisis, annual growth of the market dry-type transformers according to figures provided by Maria Andreeva, was about 25%. Therefore, with the recovery of the economy we should expect radical changes in the market of dry-type transformers.

How manufacturers respond to the crisis

Manufacturing of transformers is rather conservative industry. Therefore we cannot say that in response to the crisis producers of transformers will immediately begin to implement new programs, ideas and technology. As stressed Eugene Lyakhnitsky, today's trends in the market transformers emerged even before the crisis. Difficult year only made producers more or less to activate one or another direction. Eugene Lyakhnitsky: "I have noted several trends in the market of transformers. The first is that manufacturers and suppliers are seeking to expand its range of transformers. For example, the first Russia's factories organized the production of dry cast transformers (TSL) or transformer oil sealed (TMG), the most popular capacities - 1000-1600 kVA, then they started the development of producing transformers with capacities 25-3150 kVA. This work continues, more and more proposals appears on the market. The second trend - the emergence of special designs that require a lot of preparatory work and certification. For market TSL are, for example, frost-resistant and earthquake resistant transformers. For the market TMG - low noise and cost. The third trend was designated during the crisis - the desire to import substitution. Now we will speak in details about named (and not named) trends.

SMALL ZAG extension line

Main direction can be considered as an increase in capacity. Virtually all manufacturers of dry-type transformers with cast insulation in the past year have tried to produce models with capacity of 10 or better 20 kV. According to the company Energomash (Ekaterinburg) - Uralelectrotyazhmash ", they did last year, mastered the production of dry-type transformers power 12500 kVA and voltage class 20 kV. Similar path follows ZAO "Transformer". The company expanded the line of power transformers manufactured and released into new market segments - small transformers TMG, and 20-kilovolt cast dry and oil transformers.

Figure 3 The most powerful up to date, Russia transformer ORTS-417000/750

Figure 3 The most powerful up to date, Russia transformer ORTS-417000/750We can see "upward" trend and in the production of oil transformers. In the past year, holding "ELEKTROZAVOD" produced Russia's first ultra-high voltage transformer with capacity 417 MVA at 750 kV for the Kalinin nuclear power plant. Previously, such power transformers came only from abroad. Other manufacturers do not even have reached the absolute record, during the year significantly raised their own bar. In particular, ZAO Energomash (Ekaterinburg) - Uralelectrotyazhmash" has mastered the production of autotransformer with capacity of 125,000 kVA voltage class 220 kV, and OAO SPCТ" released seven standard models ranging from 100 to 1600 kVA, plus a power transformer of 10 kV.

Another popular trend - the development of new (atypical for a particular company) types of transformers. Even in spite of the falling popularity of dry-type transformers in this segment there went a number of manufacturers, and someone of them offers the market something that combines the quality of dry and oil transformers. For example at the JSC "ETK" BirZST "(Birobidzhan), is part of a" Voltag ", began to produce new sealed oil transformer TMG

SMALL ZAG Individuality in honor

Representatives of several companies reported an increase in interest from the customer to transformers with unique characteristics for a specific installation. Eugene Lyakhnitsky: "The flow of requests for production of non-standard transformers is great. Often we are approached by representatives of enterprises, which require a special transformer is under their production. For example, a power transformer 10 / 0,66 kV, isolating transformer 10 / 6 kV transformer capacity of 800 kVA and so on.

Similar observations gave Andrew Gusakov. "SPCT” produces transformers of own development, with not related licenses and can do custom and specific transformers. In particular, in 2009 the plant manufactured transformer substation explosion.

Small Zag import substitution

Producers of transformers involved in work about the replacement of imported parts by domestic in the end of 2008. The effect of this work was, however, limited. And before the crisis, domestic producers balanced approach to selecting suppliers and making choices not based on your residence, but based on the characteristics of its products. For example copper and aluminum wire made by domestic producers of transformers satisfied everyone. But there are observations to the foil and transformer steel, or may be in Russia it is simply not produced the desired range. Also it is enough difficult to find domestic supplier of compound for cast transformers. Therefore, by the way, in many cases the process of finding alternative suppliers was completed with the replacement of one foreign supplier to another, but with more affordable prices. Here's what experts say ZAO Energomash (Ekaterinburg) - Uralelectrotyazhmash ":" Produced elaboration of all the design documentation on import substitution and for each item found alternative suppliers, both in Russia and abroad ...

Small Zag. Search of consumers

Reduced demand from metallurgists, builders and networkers force manufacturers of transformers to find new customers. Because of this the product line keeps popping up transformers with unique characteristics. The second way - to search for buyers overseas. Viktor Kovalev: "Lack of demand from metallurgists, we had to compensate with the increase in exports and increase of supplies to energy and oil companies."

Prerequisites for growth

The demand on transformers in the coming years will grow. As noted in the study of RBC "Russia market of power”, by 2020 energy consumption will grow in developing countries at 5.2% per year, while in developed countries - at 1.4% per year. If we take Russia, the project of the investment program for 2009-2011 in the sector amount is up to 1.8 trillion. rub. In the three years planned to introduce transformer with 56 MVA capacity. And this is without taking into account the replacement of existing transformer equipment. Today in Russia on the balance of power companies and industrial enterprises is more than 20 000 substations with voltage 35 - 220 kV. Experts estimate that the depreciation of power is 50% - 70%. Corporation "Russian transformer" had calculated, that Russian companies need of transformer substations class 35 - 220 kW is estimated at not less than 400 units. year, and the need for substations Class 6 (10) kV over 30 000 pcs. year.

Analysts agree that the market of transformers will significantly increase. But wait we shouldn’t wait a rapid growth in the very near future. Deputy Head of Marketing and External Economic Relations of OAO "Sverdlovsk Plant of Current Transformers" Anatoly Bredgauer, discussing the prospects of his company, noted that 2010 sales will grow mainly due to new products. Traditional buyers won’t be very active. Related beliefs adheres Eugene Lyakhnitsky. He believes that the funds for large investment projects will most likely appear during 2011. Accordingly, then manufacturers of transformers should expect the flow of orders from private capital. But demand may begin earlier,in conditions of the beginning of full implementation of the federal building programs for the reconstruction of hydroelectric and thermal power plant, nuclear power plants.

Producers should Note

By introducing new products, manufacturers of transformers try to realize the traditional principles of any business: improving the characteristics of the product, the conquest of new niches, the implementation of additional services. Now during the design and manufacture of new models a lot of attention is paid to increase the service life, to reduce size and losses, reduction of idling. With particular technical innovations, according to Andrew Gusakova, you can draw attention to the technology without wire winding coil directly on the magnetic circuit (which can reduce the size). In addition, the interest (though still rather academic) cause production technology cores of amorphous and nanocrystalline alloys. This allows you to multiply to reduce the loss of idling. Speaking about new niches (new niches for a specific manufacturer), we can see that now it seems to be quite attractive segment of the dry-type transformers for voltage 35 / 0,4 kV power from 1000kVA for a complete set of transformer substations. Chief of VET OOO KRUELTA "Alexei Martynyuk, notes that buyers showed interest in recent years. Manufacturers of these transformers in Russia are still a rarity, but if anyone does something, as a rule, these transformers are under a certain order. To this perspective positions Andrei Gusakov adds dry transformers for voltage 20 kV for local networks. In recent years there has been a transition of urban communications from 6 and 10 kV to the more powerful lines.

Comments of experts Energyland.info

Figure 4

Eugene Lyakhnitsky, General Director of JSC "Transformer" (Podolsk):

Eugene Lyakhnitsky, General Director of JSC "Transformer" (Podolsk): - For dry-type transformers growing interest is presented by large power transformers - 1000 kVA and above, as well as voltage class transformers 20 and 35 kV. At the same time until the market niche of transformers 20 and 35 kV filled mostly foreign-made products, and only a third of Russian factories can make high-voltage class transformers themselves. That niche low-power transformers TSL until quite free. Dry transformer 100 kVA and less - a rarity for the market. But it seems to us that this segment will also actively develop.

Figure 5

Maria Andreeva, Head of the department of the transformer production OOO ROSPOL-ELEKTRO + "(St. Petersburg):

Maria Andreeva, Head of the department of the transformer production OOO ROSPOL-ELEKTRO + "(St. Petersburg): - Since 2002 in Russia is growing demand for dry-type transformers with cast insulation. This is primarily due to their ecological and fire safety, ease of installation and maintenance, low operating costs. Thanks to its compact size and low noise level, this type of equipment is increasingly being used in the reconstruction of existing substations, as well as in embedded substations in housing and community facilities. Renewal of the market dry-type transformers in mid-2009 and the activity of business and consumer transformer equipment in January 2010 suggest that market activity is resumed, and continues to grow.

Figure 6

Viktor Kovalev, director of science and innovation program OAO ELEKTROZAVOD "(Moscow):

Viktor Kovalev, director of science and innovation program OAO ELEKTROZAVOD "(Moscow): - There are several problems hampering the development of Russia's transformer. First, the defunct system of training skilled workers. Very few graduates professionally oriented to work in the industry. Secondly, the market of components and materials is monopolized. On the territory of our country there are singular manufacturers of transformer steel, electro cardboard, switching devices, paper-Bakelite cylinders. Thirdly, there is a serious backlog of normative-technical base of modern requirements. Most of the standards relating to the transformer equipment and materials used have not been revised for decades and did not fully reflect the modern requirements and possibilities.

Figure 7

Sergei Gridnev, commercial director of "BETRANS" (St. Petersburg):

Sergei Gridnev, commercial director of "BETRANS" (St. Petersburg): - During the crisis, the market of transformers will be the same. Growth will be then, when we start to build more social housing, rather than the elite, when we rebuild and modernize industry, agriculture, when the banks will provide loans under normal, reasonable interest rates, when to produce in Russia will be profitable! Last condition is possible, when the government no longer taxes stifle their producers, but rather will reduce the financial burden on them.

Figure 8

Igor Dmitriev, head of maintenance department of JSC "MRSC of Urals":

Igor Dmitriev, head of maintenance department of JSC "MRSC of Urals": - It's hard to give a clear assessment of the prevailing average of market prices. The cost of the complex process equipment depends on the customer's requirements and can vary greatly. It depends on the equipment, and a complete set of the most critical nodes. Earlier in the formation of long-term plans the cost of the transformers was calculated from the ratio - 1 MBA about 1 million rubles. Currently, prices have fallen. Moreover, this proportion is reduced depending on the growth of power. In servicing the same way there has been a significant reduction in the cost of expenses. This is due to the use of more reliable components, as well as monitoring of transformers. With the application of these components significantly increases the reliability of transformers, increases the time period.

Figure 9

Maxim Egorychev, Sales Director of transformers of JSC "Group of Companies ElectroShield"-TM Samara:

Maxim Egorychev, Sales Director of transformers of JSC "Group of Companies ElectroShield"-TM Samara:More problems in the transformer production, we do not see. It should be noted that the development of technologies in this industry is at a standstill. Transformers are made virtually by the same technology as ten years ago. We have improvements in the manufacturing process, of course, but they are rather insignificant. In general, the science has not invented anything new for the distribution and transmission of electricity.

This material was prepared by Andrey Gubanov, EnergyLand.info

Translation: Mukhametyanov Timur, EnergyLand.info

Links (russian version):

Innovative solutions in the transformer

The crisis won’t drench them

Transformer’s market: three phases of crisis?