Not so long ago, at one of the exhibitions, a display with bright lamps has caught my eye. Were they LED? Halogen? Turned out those were induction lamps. As I was told at the stand, that is an advanced innovation technology which will successfully compete with LEDs in the years to come. Now, that is a doubtful claim. EnergyLand decided to look into the matter.

Meet an induction lamp

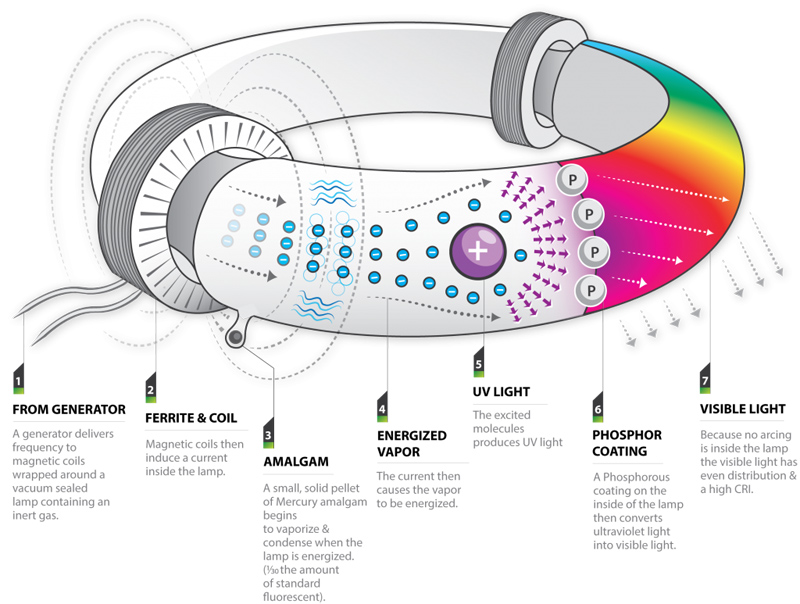

As the name implies, the lamp operation is based on the electromagnetic induction principle. The lamp consists of a special bulb with inside fluorescent coating, a ferrite-core induction coil, and a high-frequency current generator. Flowing through the inductor, high-frequency current induces the alternating electric field which results in a gas discharge in the bulb. The induced current causes the acceleration of free electrons which collide with mercury atoms resulting in their excitation. As these excited mercury atoms fall back to their stable state, they emit ultraviolet radiation. In turn, the ultraviolet radiation is absorbed by the fluorescent coating inside the gas discharge bulb causing light to be emitted.

“One of the main advantages of induction lamps is their ultra-long lifetime”, explains Mikhail Isupov, Senior Fellow of the Institute of Thermal Physics affiliated to the Siberian Branch of the Russian Academy of Sciences, Novosibirsk. “The lifetime of common gas discharge lamps is about 10 000 hours. For high-power (10s kW) lamps, it is reduced to a few hundred hours due to fast destruction of electrodes. A transition to electrode-free (induction) operating principle allows eliminating the destructing elements (electrodes) completely and extending the lamp lifetime by about ten times.

However, common use of induction lamps is prevented by the high prime cost of their production. The design of a gas discharge bulb is more complicated compared to common fluorescent lamps. Plus, a high-frequency power source is used”.

Operating principle of an induction lamp

Through the West to the East

It turned out that theoretically, induction lamps, like many other inventions related to electricity, root back to discoveries made by Nikola Tesla. A prototype of an induction lamp was created by General Electric in the 1960s. In the 1990s, Philips has introduced the first commercial product into the market – QL lamps which were based on the same technology. Osram elaborated its own design of an induction lamp, too (Endura), and GE produced a lamp with a consonant name Genura. The long and the short of it is that basically all leaders of the lighting engineering market gave credit to this technology. But it only lasted up to a certain time. There is only one induction lamp in today’s product range of Western manufacturers. This brings up the question: why?

“In fact, for a period from 1995 to 2007, Philips has manufactured a family of QL 55 W, 85 W, 165 W lamps”, told us Viltaly Stepanov, Candidate of Science and Technical Advisor at Philips. Lighting Solutions. “A few series of lighting fixtures were manufactured for those lamps. That was a “niche” product with unprecedentedly long lifetime: at first 60 000, and then 100 000 hours. It was the best when there were issues related to maintenance access to lighting equipment, e.g. in very high halls of shopping malls, or where maintenance was associated with inconveniences for facility users such as in airports or railway stations.

The price of those lighting fixtures and lamps was rather high. And that was the main obstacle for common use of those products. The demand for induction lamps turned out to be poor, and when LED lighting systems with similar lifetime and many other advantages came to the market, QL lamps were discontinued.

Induction lamp made in China

Induction lamp made in China

Nowadays, induction lamps represented on the market are generally made in China. Russian dealers of those products claim that production of induction lamps requires manual assembly, and that is the reason why they are not profitable in Europe. It means that Western manufacturers have lost a competitive battle with their Chinese colleagues. By the way, in spite of mastered mass production, Chinese induction lamps are still expensive: about $100.00 per one lamp along with a power source.

And here is the finishing touch to the West-to-East opposition on the induction lamp market. For six years, up to 2011, Osram (Germany) has been in litigation with Hongyuan (Shanghai) that produced LVD lamps, for infringement of Endura manufacture patent. Eventually, the court held that even though the technical solutions were quite similar, they were not exactly the same so there was no infringement on the part of Hongyuan. As a result, the latter obtained a patent on LVD lamps and sank its teeth into development of worldwide markets.

Russia has always had its own way

In our country, this theme has gained momentum, too. Thus, in the Institute of Thermal Physics affiliated to the Siberian branch of the Russian Academy of Sciences, a family of induction lamps was developed, each type designed for a different purpose. First of all, there were powerful high-pressure mercury lamps 5-50 kW for lighting of large outdoor areas such as construction sites, open pit mines, railway stations, etc., and for photochemical reactions. Second of all, there were neon low-pressure lamps 100-1000 W for architectural lighting of buildings and signal lighting. And finally, low-pressure mercury lamps 50-5 for UV decontamination and photochemical reactions.

It is evident that the prime cost of a Russian induction lamp does not let it compete with mass Chinese production. However, the Siberian branch of the Russian Academy of Sciences does not abandon the idea of development of such an interesting direction. In fact, they are now focused on specialized types of lamps that have not been produced by anyone in the world so far. First of all, those are electrode-free UV lamps for decontamination, and EFUV lamp-based modules used for water treatment.

Induction lamp for outdoor lighting

Induction lamp for outdoor lighting

A lighting fixture for a lamp

But back to induction lamps used for lighting. Vitaly Stepanov fairly notices that nobody wants the lamp itself if there is no corresponding lighting fixture. We have to understand that induction lamps usually require a special lighting fixture, and the latter has to be rather big. This is with the exception of Genura which has a standard E27 cap, but on the other hand, its lifetime – 15 000 hours – is not really different from other compact fluorescent lamps.

That probably was the lack of corresponding lighting fixtures on the market that pushed a Russian company IEK to develop such a product.

“The downside of induction lamps is that only specially designed reflectors may be used due to the lamp’s toroidal shape, and only then correct distribution of the light flux may be ensured”, explains Elizaveta Shonina, Chief Executive of the Lighting Engineering Department at IEK Group. “That is why we propose fully equipped lighting fixtures where a specially designed reflector guarantees the best distribution of the light flux and ensures uniform lighting.

Mass production of FSP 4001I lighting fixtures has commenced at the end of 2012. Before proceeding to the production process, our company has performed a thorough market survey. According to our observations, every year prices on induction lighting fixtures go down, even if such decline may seem too subtle. And speaking of industrial and trading facilities, metal halide lamps and even fashionable LED lamps get substituted for induction lamps little by little. The latter ones become more and more popular because they outperform the very same LEDs by many parameters”.

Induction fluorescent lamp

Induction fluorescent lamp

Pro-induction phantasies

Here, we encounter the main point at issue: what are better, light-emitting diodes or induction? Unfortunately, focused on promotion of their products, or hoping for customers’ ignorance, some Russian dealers of LVD lamps and other less known Chinese brands start spinning facts. As a result, among plane exaggerations and fair mistakes, even real information about advantages of induction lamps may arouse mistrust.

For example, they claim that light-emitting diodes may not be dimmed, or that the warranty life of LED lighting fixtures is less although many manufacturers guarantee the same five years as for the induction lamps. Comparative information sheets show that luminous efficiency of light-emitting diode lamps is the same as in induction lamps, which is only 80-110 lm/W whereas as long as two years ago, 120-130 lm/W was already considered to be the standard luminous efficiency of diode office lighting fixtures, taking into account maximum parameter of 160-170 lm/W. And in 2013, Philips has announced a prototype of a lamp with luminous efficiency of 200 lm/W.

Another funny promotion stunt is a weird parameter called “effective luminous efficiency”. According to sellers, it is twice as high as “nominal luminous efficiency” in induction lamps, i.e. about 160 lm/W. Allegedly, this parameter reflects perception of light with a human eye. Then why don’t we multiply the actual luminous efficiency by three and obtain “cosmic” 240 lm/W? Plus, there is no clarification as to what instrument should measure the “effective luminous efficiency”.

Assembly of lighting fixtures FSP 4001I for induction lamps

Assembly of lighting fixtures FSP 4001I for induction lamps

Better than light-emitting diodes?

Even if we brush away such surrealistic arguments, it is not easy to find out the truth. Generally, the most beneficial parameters of induction lamps enlist high luminous efficiency, low energy consumption, high color rendering index, instantaneous start, long lifetime, and unlimited number of on-off cycles. What a professional may say about that?

“We have to understand that based on principle of generation of light radiation, induction lamps are similar to fluorescent lamps with the only difference is that they are electrodeless”, explains Vitaly Stepanov. “For the rest, they are plain fluorescent lamps with all their advantages and disadvantages. The advantages are as follows: high quality of emitted spectrum (which is due to fluorescent coating), relatively high luminous efficiency (up to 90 lm/W), stable lighting parameters (light flux deterioration is 10-15% if there are any measures taken to prevent fluorescent coating against mercury contamination).

The disadvantages are: dependence of light characteristics on the environment temperature. That is why induction lamps are mostly used for indoor lighting. The best characteristics are achieved at 20°С above zero, and at freezing temperatures, the light flux gets significantly lower.

If we try to compare induction lamps with light-emitting diodes, such comparison must be made by using specific examples. Characteristics of specific items (lamps and lighting fixtures) must be compared. Also, lighting parameters and economic values must be assessed under the specific operating conditions”.

Indeed, imagine you are comparing the same induction lighting fixture with a no-name Chinese LED first, and then, let’s say, with a genuine Cree lamp (US). In the former case, the induction lamp will win in terms of technical characteristics, and in the latter case – in terms of the price.

And of course, it is very important to consider the lamp purpose. Light-emitting diodes are definitively more advantageous for home and office lighting as well as for outdoor lighting in the Russian climate. But speaking about warehouses, industrial and trading premises, there is a reasonable chance of success for induction lamps.

Russian lighting fixture for an induction lamp

Russian lighting fixture for an induction lamp

To be or not to be?

Opinions of our experts about the future of induction lamps have turned out to be completely opposed to each other. It is hardly surprising considering that those opinions reflect market strategies of each specific company.

“Unlike light-emitting diodes, the induction technology is almost perfect”, thinks Elizaveta Shonina. “And even though we do not forecast any revolutionary development, with due account of all the advantages of induction, we expect that in the nearest 5 years, customers will appreciate its benefits and will move on to the induction lighting”.

As for Vitaly Stepanov, he confesses himself that he does not see any prospects for utilization of those lamps because their main advantage – long lifetime – has not been much in demand.

“Apparently, induction fluorescent lamps will not be able to compete with LED lamps in the long term”, agrees Mikhail Isupov. “LED lamps are still too expensive as well, but their production cost gets lower and lower without affecting their efficiency and lifetime which are almost the same as efficiency and lifetime of induction fluorescent lamps. But in this case, we are only talking about lamps used for lighting. In many other fields, LED technology does not work. For example, today there are no powerful UV LEDs that could be used for decontamination. And here, induction lamps could find their use and replace common electrode UV lamps”.

Well, we would say there is no point to make any decisive conclusions yet. Plenty of companies throughout the world promote the idea of a light-emitting diode revolution, but off the mainstream, there is another spur growing towards evolution of energy efficient lighting. And we dare say it has a right to life in those niches where it fits the best. But only “natural selection” in terms of customer preferences will help us to give a more definite answer to that question over time.

Ekaterina Zubkova

On the 1st photo: Induction lamp

(С) Медиапортал сообщества ТЭК www.EnergyLand.info

Оформить подписку на контент Looking for authoritative content?

Копирование без письменного разрешения редакции запрещено

Read also:

Правило Legrand: современный офис – это эффективное освещение каждого квадратного метра

Курс на энергосбережение: что надо поменять

На Новочеркасском электровозостроительном заводе стартует проект по энергосбережению

«Не знаем, чего ждать от тарифов»

Компания «Газпром нефтехим Салават» смонтировала блок удаления кокса

GE Energy предлагает экономичное решение для учета электроэнергии

Induction lamp made in China

Induction lamp made in China Induction lamp for outdoor lighting

Induction lamp for outdoor lighting Induction fluorescent lamp

Induction fluorescent lamp Assembly of lighting fixtures FSP 4001I for induction lamps

Assembly of lighting fixtures FSP 4001I for induction lamps Russian lighting fixture for an induction lamp

Russian lighting fixture for an induction lamp