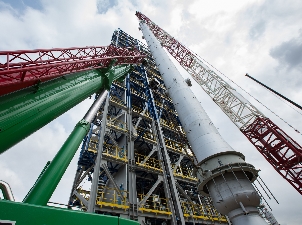

The installed reforming column — part of the secondary oil refining process, resulting in the production of high-performance-gasoline components — weighs 150 tonnes, and is 60 metres high.

The new column consists of four reactors arranged one on top of the other, into which gasoline fractions will flow from the crude distillation unit (CDU) for interaction with catalyst. Thanks to modern continuous-recovery technology, the process of regenerating catalyst activity occurs without any pause in production, allowing further improvements in production efficiency. The Euro+ CORU facility has capacity to process one million tonnes of crude per year.

Construction of the Euro+ facility began in 2016, with 20 percent of works now complete.11,600 piles have now been driven into the earth, and filled with 24,000 tonnes of concrete — 75 percent of the total volume. Nine thousand tonnes of metal structures have been delivered to the plant. Twenty two of a total 31 pieces of major equipment have been installed. NIPIGAZ, a leading Russian project management, procurement and construction organisation, is general contractor on construction of the Euro+ facility.

Construction of the Euro+ facility is a key project in the second phase of the thoroughgoing modernisation of the Moscow Refinery currently being undertaken by Gazprom Neft since 2011. Commissioning of the Euro+ facility is expected to increase the yield of light petroleum products, facilitate the move towards a four-year run life, improve energy efficiency, and significantly reduce environmental impacts.