It is envisaged that the companies will design the robotic welding cell to be used in the fabrication of the 3-cubic-metre stainless steel boxes to be used to safely store decommissioning waste. Mainly it is referred to the UK's decommissioning waste, but the robotic welding cell will become available on a commercial basis for the global industry afterwards.

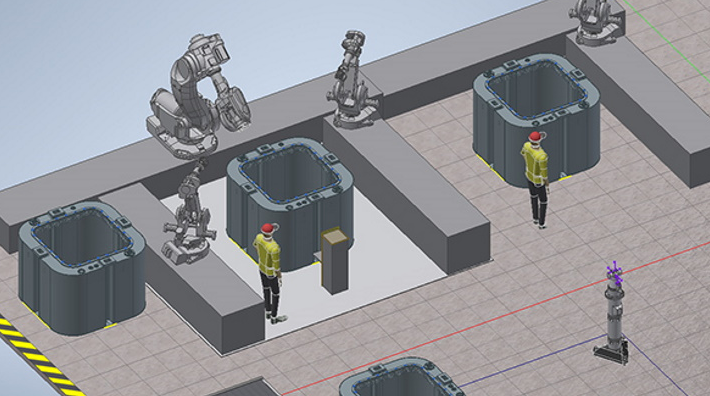

The Nuclear AMRC is developing a new technology demonstration facility at its Rotherham research factory. The heart of the facility will be a robotic welding cell, which includes: the integrated welding automation, container manipulator, robotic welding arm and K-TIG welding systems, as well as the automated pre- and post-weld inspection systems deployed for real-time quality checking.

K-TIG, which has been working with Nuclear AMRC since 2019, has developed a patented keyhole welding technology, which can produce welds 10-100 times quicker than conventional tungsten gas arc welding, joining metals up to 16mm thick in a single pass.

«A successful conclusion to the collaboration would be to provide UK manufacturers with a turnkey solution for the fabrication of the products,» explained Sean Murphy, strategic relationship manager at the Nuclear AMRC. «This will help to ensure a strong supply chain, maintaining safe, repeatable quality and delivery.»

K-TIG said it expects some 15,000 nuclear waste containers to be fabricated and procured by Sellafield as part of its GBP1.5 billion (USD2.0 billion) procurement plan, currently scheduled to commence in 2023/24.